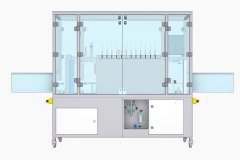

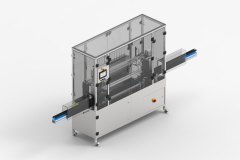

Blow-out module HLB 120

Blow-out module HLB 120

The containers to be blown out are rotated 180° during the cleaning process.

The machine of the HO-MA blow-out module series is designed for e.g. the following segments:

Pharmacy-free medicines – Healthcare – Diagnostics – Food & non-food products

All machines always meet our high-quality standard

- Standardized technology

- Space-saving design

- Gentle object transport

- Fast size part changeover

- Innovative operating concept

- Competent service

Options of the Blow-out module HLB 120

- Vacuum unit on drawer, if central extraction not available

- Ionising station according to task

- Moulded containers by arrangement

- etc.

Combination possibilities with the other HO-MA modules of the series

- Product feeders for glass, plastic containers (stable and non-stable)

- Filling module HRF 35 in a wide range of configurations

- Capper module HRC 35 in various configurations

- Labelling module HRL 35 with or without printing option

- Product transfer or product buffer systems

In-line or corner installation possible

Suitable for the following blowing tasks |

|

|---|---|

| Products | Round containers made of glass or plastic By agreement: shaped containers and containers with angular transition cylinder to bottle neck |

| Cleaning type | Containers are rotated by 180° degrees (motorized drive) Cleaning nozzle in container with suction flange at the filling opening |

| Production output | Up to 120 packs/min. depending on the shape and the filling opening of the container. |

| Product dimensions | Up to Ø 55 mm Up to 170 mm height From 7 mm filling opening |

Basic machine |

|

| Dimensions | Basic machine approx. 2,000 mm x 700 mm x 2,100 mm Plus infeed and outfeed protection, continuous conveyor belt |

| Extraction | Can be connected to customer's system or with vacuum unit (extractable installed) |

| Pneumatics | Sterile filter in the basic equipment |

| Antistatik | Optional - Ionizing station, position to be coordinated |

Format change |

|

| Cleaning | Cleaning nozzles with quick-change function (clamping lever) |

| Lifting device | Acceptance on Centerline, Optional - adapters according to container -shape, -height, -flexibility of the containers. |

Further advantages of the HO-MA - HBL 120 blow-out station |

|

| Frame | Stainless steel frame with large doors for optimal accessibility Vacuum unit extendable |

| Format change | Optimal accessibility Format settings positioned above sliding plane |

Control |

|

| Machine control system | Siemens or B&R mit 7“ Panel |

Stand alone or combinable with |

|

| Bottle erector HBS or FAS | |

| HO-MA HR series Filling, closing and labeling | |

We will be happy to send you more information.