Machinery solutions

Feeding and transport systems

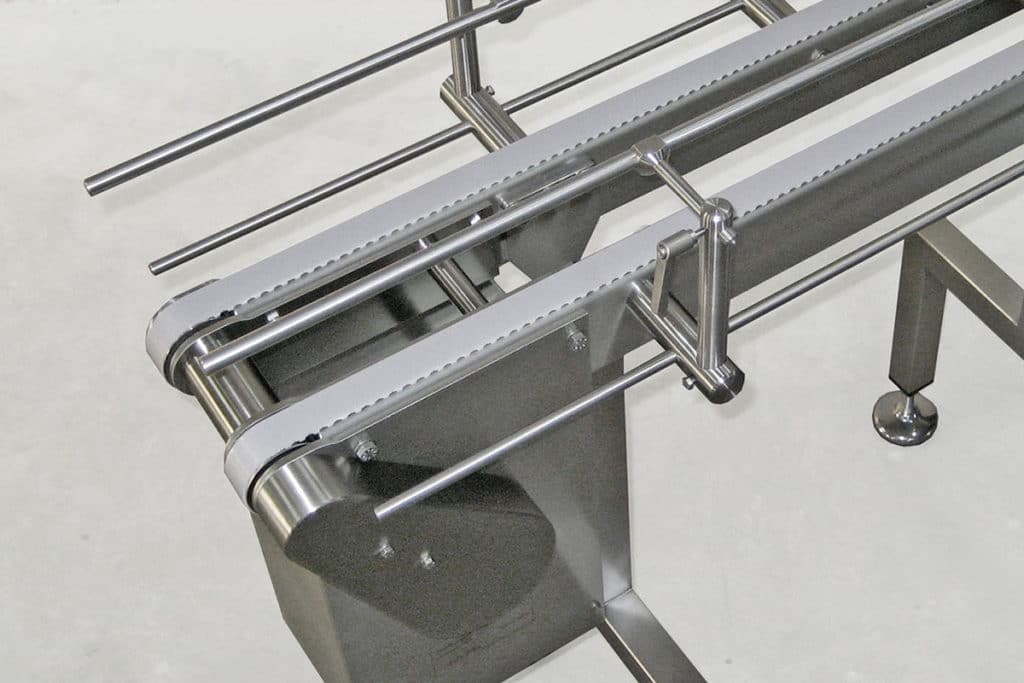

Curve-enabled flush-grid belt conveyor

The HO-MA curved belt adapts to your transport and feeding requirements. Product and space optimized it offers a flexible and seamless transport.

Curved mat chain belt

Due to its elastic design, the mat chain belt is particularly space-saving and can vary in the radius of the curve.

Deflecting turntable

The HO-MA deflection turntable enables a flexible and line true transport technology. Especially adapted to your machine line, the HO-MA diverter turntable flexibly adapts the feeding of your products.

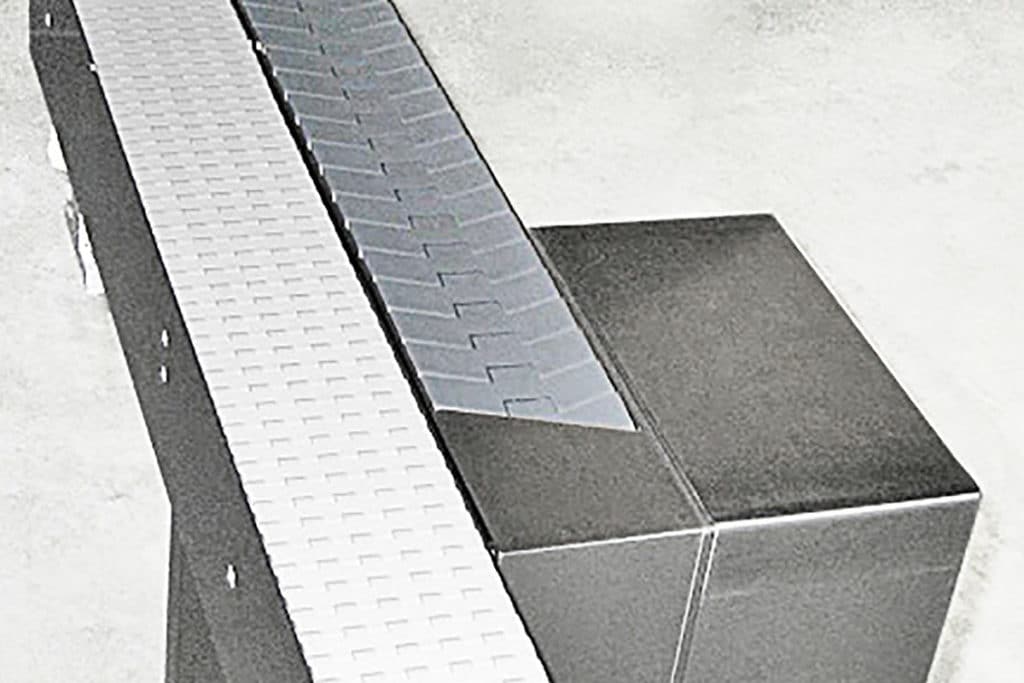

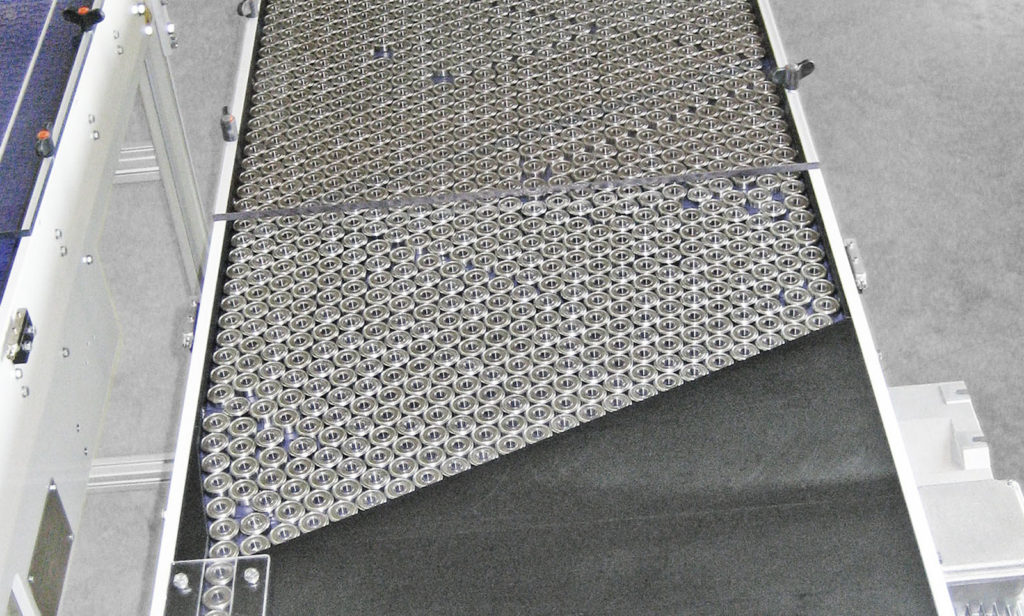

Flush-grid belt conveyors

The linear HO-MA conveyor belt offers an individual transport and feeding solution adapted to your requirements and conditions.

Space-saving conveyor belt with a minimum width of 55 mm / suitable for small parts.

Mesh chain conveyors are to be chosen especially for high capacities. They are easy to install and replace.

Belt bands

Due to their non-slip properties, belt conveyors are particularly suitable for small-sized and lying, bulky products such as bags.

The design is possible as a simple belt conveyor belt or as a multi-track belt conveyor.

Ascending conveyor belt

Vertical / ascending transport solution

With an adjustable incline, the ascending conveyor belt adjusts to the height differences between the upstream and downstream machines.

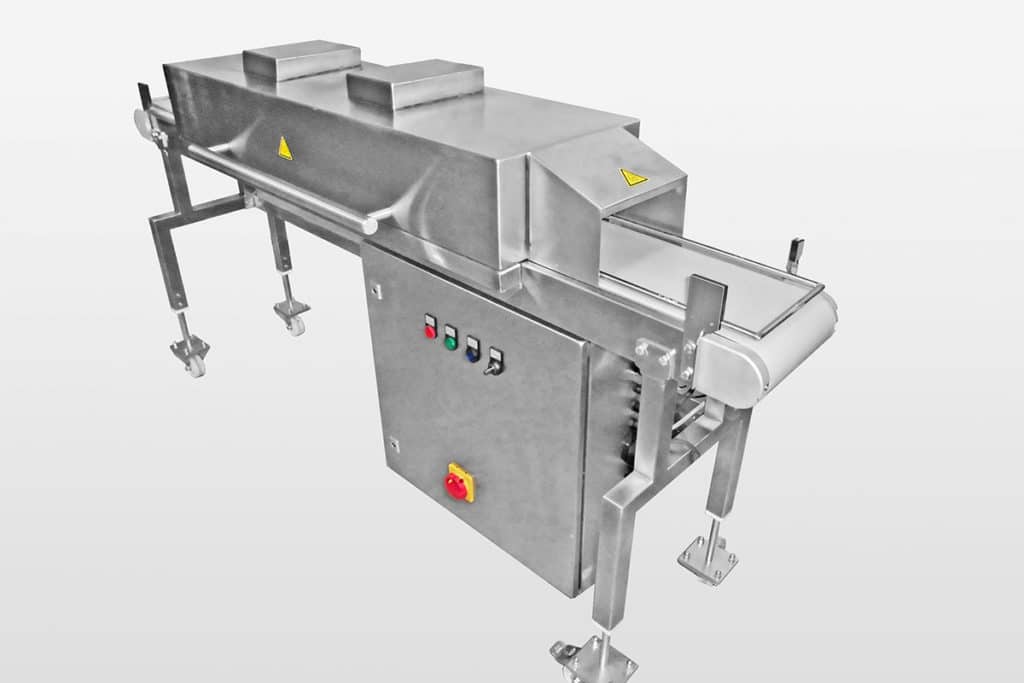

Disinfector belt

Gentle disinfection system for the food industry.

For: food / pharma products / heat-sensitive products

Naiopur disinfector

Gentle disinfection system for the food industry.

For: Seeding material / seed / cereal / grains / herbs / spices / nuts / beans

PRU (Product Rambler Unit)

The PRU is the gentle feeding solution for syringes. The syringes are separated by round belts for further processing.

Interested? Please get in touch with us.

Our team is happy to answer any of your questions.

STS Syringe Transport System

STS Syringe Transport System

The HO-MA STS syringe transport system is an innovative transport system for usually round products with a collar. The angle of incline is adjustable up to approx. 30° and several STS systems can be coupled.

The modular design has resulted in a compact and cost-optimised machine that can not only be optimally adapted to the PUR plate conveyor but also as a "stand alone" transport unit to your machine.

In combination with HO-MA's extensive product portfolio in feeding systems, we will find the optimum solution for your application.

Interested? Please get in touch with us.

Our team is happy to answer any of your questions.

Turntable

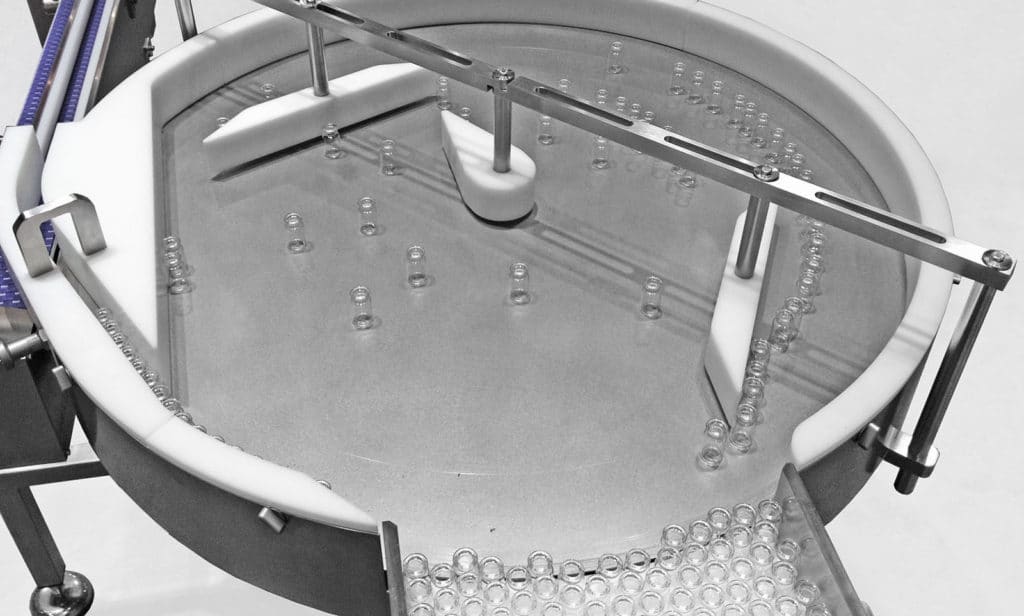

Infeed turntable (ADT)

The HO-MA turntable is suitable for stable products, stores your products and feeds them continuously to the transport process Direction of rotation and product adaptation are selectable.

Outfeed turntable (EDT)

The HO-MA turntable is suitable for stable products, stores your products and feeds them continuously to the transport process Direction of rotation and product adaptation are selectable.

Interested? Please get in touch with us.

Our team is happy to answer any of your questions.

Ascending conveyors

Ascending conveyors DE (Standard)

Continuous transport and feeding at adjusted heights and angles. The HO-MA Ascending Conveyor DE is optimized for a small feeding quantity.

Ascending conveyors DES

Our ascending conveyors (dosing elevators) are designed for different volumes. Products are fed as bulk material to downstream machines.

Ascending conveyors with belt DEB

The HO-MA Ascending Conveyor DEB continuously feeds your products into the production process with a larger volume.

Ascending conveyors vertical DESB

The HO-MA ascending conveyor DESB is the optimal solution for a right-angled and continuous transport and feeding solution.

Interested? Please get in touch with us.

Our team is happy to answer any of your questions.

Separate and storage Systems

PRU (Product Rambler Unit)

The PRU is the gentle feeding solution for syringes. The syringes are separated by round belts for further processing.

Buffering turntable

The HO-MA buffer turntable is suitable for stable products, stores your products and feeds them continuously to the transport process. Direction of rotation and product adaptation are selectable.

Buffering table (conveyor belt)

The HO-MA buffer table ensures a smooth transport process. Our buffer tables buffer, store and collect according to required performance, formats and space conditions.

Conveyor belt for buffering large quantities

- high volume

- single track conveyor belt

Bi-flow belt

The HO-MA BI-FLOW-BAND ensures a smooth and synchronized transport during the production process.

Unpacker

Mobile placement system for rapid unpacking.

For: Tins / vials / containers / trays

Interested? Please get in touch with us.

Our team is happy to answer any of your questions.

Bottle unscrambler

Bottle unscrambler

The HO-MA bottle unscramblers sort and separate plastic containers such as bottles and similar in different shapes and sizes, which are fed as bulk material. In principle, the containers coming from a storage container are sorted, set up, separated and transported to a downstream plant.

In order to meet the tasks and requirements, we design your tailor-made solution

BOTTLE UNSCRAMBLER with air FAS

The HO-MA bottle unscrambler positions bottles in the correct production position. The bottles are fed to the HO-MA bottle unscrambler as bulk material.

By an interaction of sensors and pneumatics upside down bottles are detected and transported back to the sorting process.

Sorted in the correct position, they are positioned by an individually adapted format part in such a way that they are directed onto a conveyor belt and smoothly integrated into the production process.

Bottle unscrambler without air HBS

Instead of air, we use pure mechanics. Bottles are turned and aligned with the help of a wheel. You benefit from low-noise and energy-saving processes. High performance and clean room suitability are convincing.

Interested? Please get in touch with us.

Our team is happy to answer any of your questions.

Sort & arrange

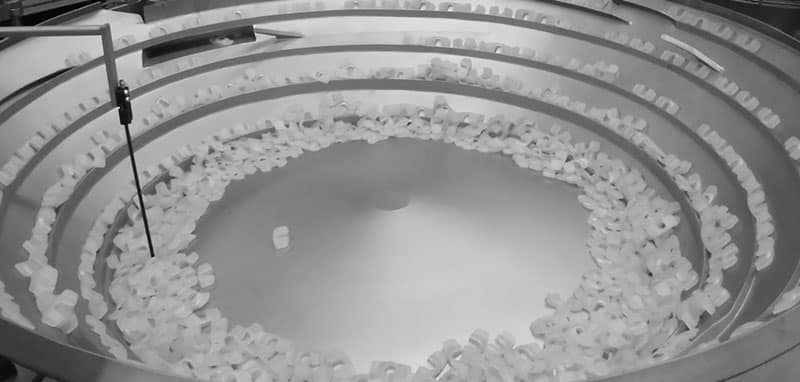

Vibrating conveyor bowl

With vibration sorting, small batches / quantities can be processed individually up to 200 pieces per minute.

Depending on the type of object, we recommend different designs / types - conical, cylindrical or stepped.

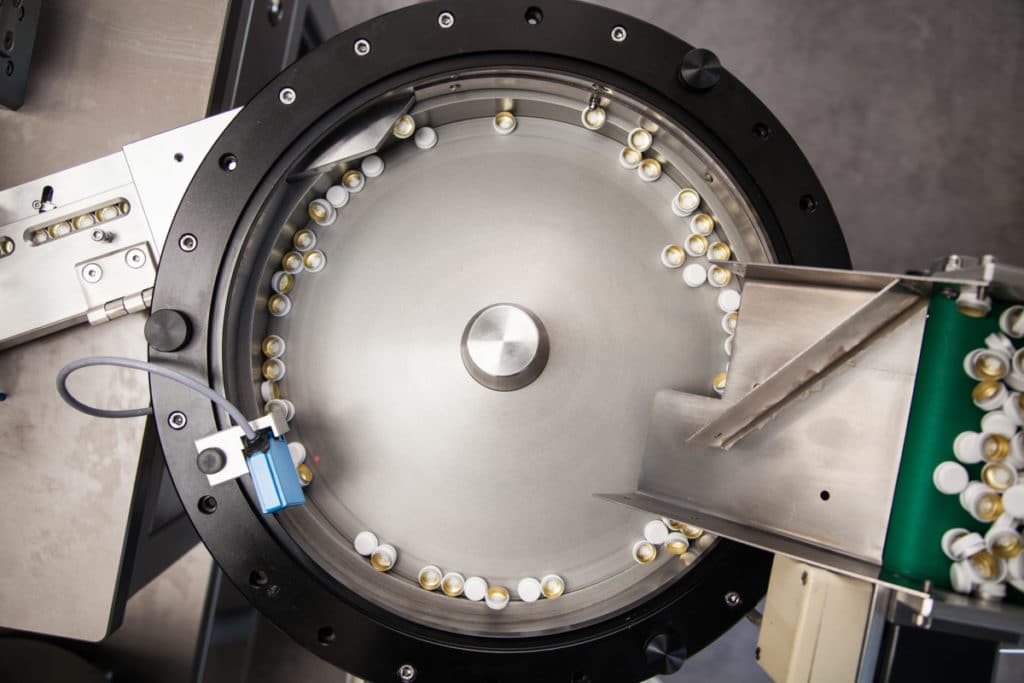

Centrifugal feeder

Centrifugal sorting is used for high capacities up to 800 pieces per minute.

The quiet and gentle sorting is particularly suitable for plastic objects.

Depending on object type and size we recommend different versions ZF-350, ZF-500, ZF-800.

Due to the user-friendly and space-saving design, it can be combined with other machines and systems.

Interested? Please get in touch with us.

Our team is happy to answer any of your questions.

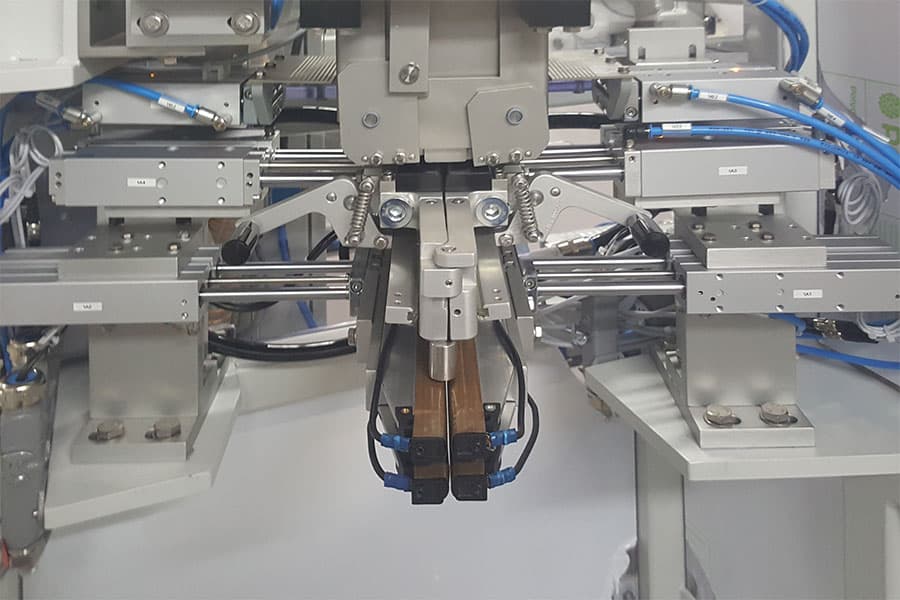

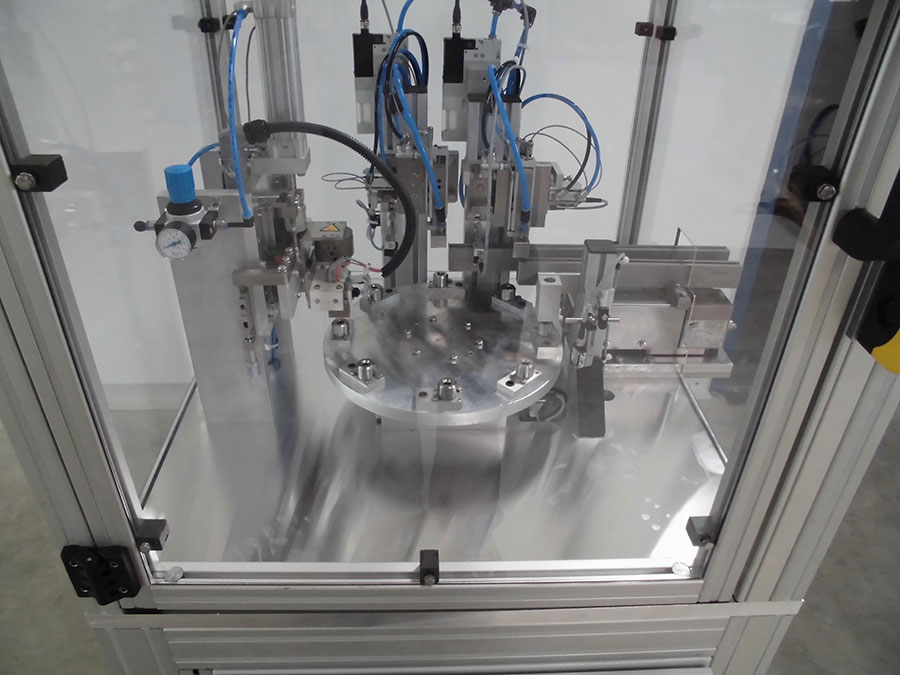

Special solutions

Sorting- and feeding System

combined line solution

1-lane infeed with distribution on 3 lanes for blow-fill products

3-lane infeed with distribution on 6 lanes for vial adapter products

Semi-automatic

These can be designed for a wide variety of objects and applications for manual operation or as fully automated systems.

In certain applications the combination of both types of solutions is also possible.

Another possibility is a modular approach, which allows the customer to expand the capacities and the technical level later on according to his current needs.

Individual stations can be connected by a conveyor belt system, or the parts can be transferred manually.

Automation

A fully automated solution cannot manage without reliable automatic feeding and sorting equipment.

In this area we cooperate with well-known manufacturers of vibration and handling elements.

The automatic and semi-automatic solutions can also include camera sensors or smart cameras.

Interested? Please get in touch with us.

Our team is happy to answer any of your questions.