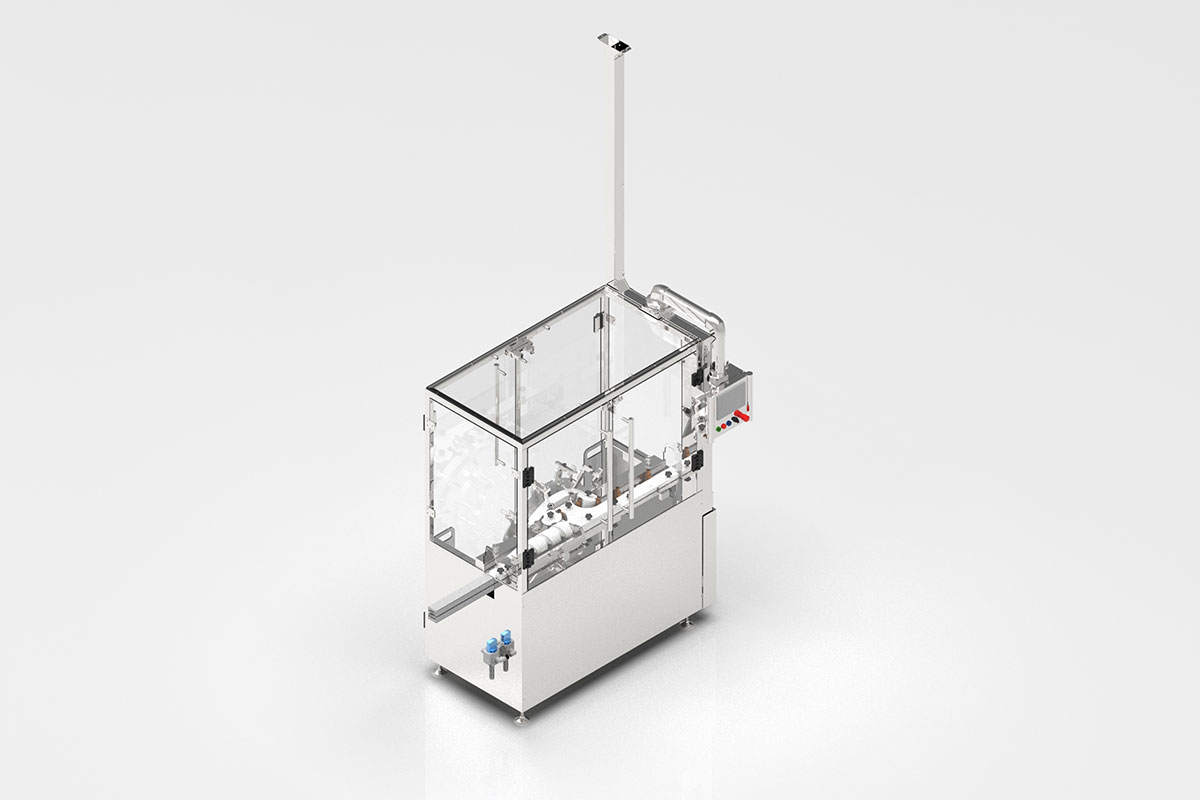

Blowout machine with integrated conveyor belt

Blow out machine with integrated conveyor belt

for bottles or tubes

An investment that pays off and increases the product quality in your production. You also save up to 70% on transport packaging and its disposal. You need less unpacking time and significantly less floor space. Your bottles are cleaned of the last impurities directly before filling. A high-pressure air jet removes even the last particles from the bottle. Antistatic devices ideally prepare plastic bottles for cleaning and then facilitate filling with low-viscosity liquids.

The blowing machine is ideally located between the bottle erector and the filling machine, or between a turntable from which the bottles are fed and the filling machine.

All bottles are fed to the blowing machine in a single lane, where they are blown out with air. A sterile filter first cleans the air of particles and bacteria down to a size of 0.0002 millimeters before it is blown into the bottle. The air stream removes all loose particles that are in the bottle, such as glass splinters, dirt, dust or remnants of packaging films.

The blowing machine can process the following products: Round and oval bottles made of glass or plastic and bottles in transport containers. An anti-static system optimally prepares plastic bottles for the cleaning and filling process.

The maximum bottle volume is 500 ml with a bottle diameter of up to 100 mm. Bottle heights of up to 220 mm are possible. The maximum output can be up to 400 bph, depending on the bottle size.

In a continuous motion, the bottles pass through a rotor, are turned upside down, discharged and returned to a conveyor belt. The dirt is collected in a collecting tray or directly at the bottle neck and sucked off.

Performance data |

|

|---|---|

| Products | for bottles or tubes |

| Bottle diameter | 15 to 85mm |

| Bottle height | 40 to 165mm |

| Inner diameter of the mouthpiece | from 10mm |

| Bottle material | Glass / Plastic |

| Flow rate | 50 to 400 bpm |

| Format changeover time | <15 min. |

| Format changeover | Exchangeable sets |

| Dirt extraction | central 2.5m3/min. |

| ransport bandwidth | 83mm |

| Running height | 900mm +/-50mm |

Electrical data |

|

| Power | 5 kVA |

| Current | 7,3 A |

| Voltage | 400V/N/PE |

| Frequency | 50/60 Hz |

| Main connection line | 4 mm2 |

| Main control cabinet | 600x600x210mm |

| Feeder insertion | From below |

| Control cabinet version | Stainless steel |

| Power loss | Ca. 900W |

| Control voltage | 24VDC |

| Control | SPS |

| Bedienelemente | Touch panel, user language selectable |

| Machine signals | potential-free |

| Speed control | via frequency converter |

Compressed air |

|

| Mains pressure | min. 5 bar |

| Mains connection | d12mm, plug-in connector |

| Consumption | Depending on the respective version |

| Sterile filter <0.2my | integrated and monitored |

Facility weight |

|

| Net | Ca. 2500kg |

| Dimensions | see layout |

Options |

|

| Ionisation for plastic bottles | possible |

| Dirt extraction decentralised | possible |

| Dirt collector with drawer | possible |

| Other options | on request |

We will be happy to send you more information.